Die Aussteller der Automotive Interiors Expo Europe repräsentieren das A–Z der Fahrzeuginnenausstattung. Ihre Produkte werden von so gut wie jedem Autobauer der Welt genutzt, von Ferrari, Maserati, McLaren und Porsche über GM, Volkswagen, Jaguar und BMW bis hin zu Kia, Toyota und Chery – um nur einige wenige zu nennen!

Bei dieser Messe dreht sich alles um Qualität, Farbe, Textur, Haptik und Innovation. Ein wichtiges Thema der Expo sind spezielle Oberflächen und so bieten die teilnehmenden Firmen beispielsweise Kunststoffverbundwerkstoffe und Masterbatches, metallisierte Kunststoffe und Kunststoffe in Chrom-Optik, aber auch Heißfolienprägung und Folienhinterspritzung (FIM) an.

Hier finden Sie ein breites Spektrum an Geweben, akustischen Werkstoffen, formgebenden Materialien und Schaumstoffen, Verbindungselementen und Klebesystemen, Beleuchtung und mehr! Die Messe ist für Tier-1-Lieferanten ebenso ein Muss wie für die Innenraumdesigner von Automobilherstellern, die in der sich rasant verändernden Welt der Materialien, Oberflächen und Technologien für einen optimalen Gesamteindruck auf dem Laufenden bleiben wollen.

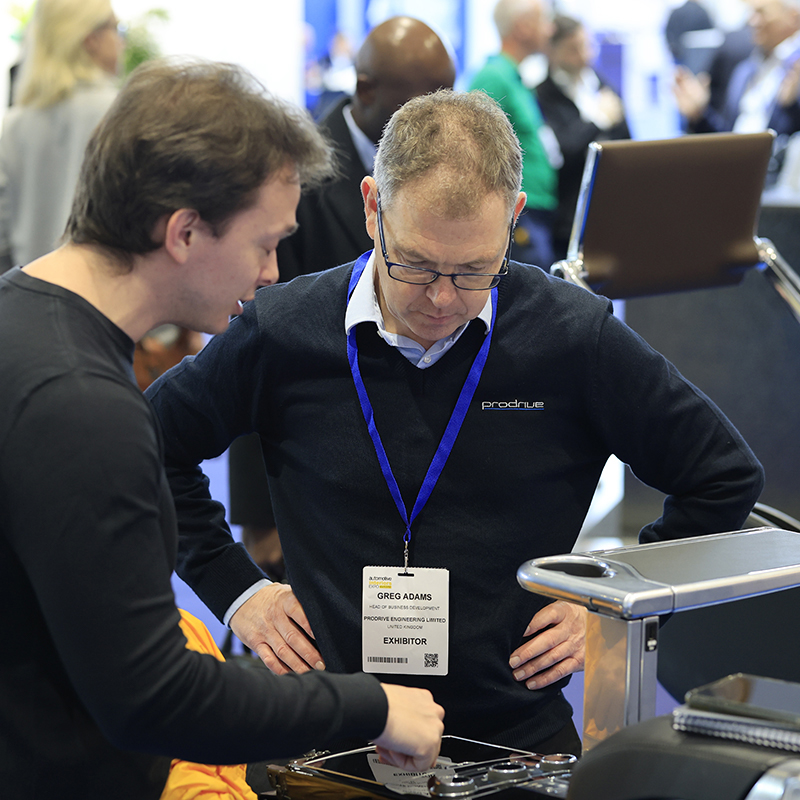

Die Messe ist für Designteams und Einkäufer gleichermaßen wichtig und bietet eine Fülle von Exponaten, die Innenausstatter wie auch Tier-1- oder Tier-2-Komponentenhersteller interessieren werden. Auf dieser Expo stehen Lösungen im Vordergrund – es gibt eine Unmenge innovativer Produkte zu sehen!

Seien Sie persönlich mit dabei, wenn wir uns vernetzen, Ideen austauschen, Innovationen entdecken und uns auf eine bessere, effizientere und nachhaltige Zukunft vorbereiten. Klicken Sie hier, um sich zu registrieren.

Sehen Sie sich unsere Interviews mit Ausstellern aus den letzten Veranstaltungen an

Landesmesse Stuttgart GmbH

Messepiazza 1

70629 Stuttgart

Germany

+49 711 18560-0